We are pleased that Dr. Michael Fisher has joined the FTCLDF website as a regular contributor. Dr. Fisher is a retired United States Department of Agriculture (USDA) Food Safety and Inspection Services (FSIS) veterinarian, bringing decades of experience enforcing FSIS regulations during the slaughter and processing of animals for which the USDA provides inspection services. Dr. Fisher is thrilled to bring you his expertise and guidance to help you navigate regulatory compliance. His goal is for small, USDA-inspected meat processors to succeed and to understand how to best maintain compliance and reduce regulatory issues.

We are pleased that Dr. Michael Fisher has joined the FTCLDF website as a regular contributor. Dr. Fisher is a retired United States Department of Agriculture (USDA) Food Safety and Inspection Services (FSIS) veterinarian, bringing decades of experience enforcing FSIS regulations during the slaughter and processing of animals for which the USDA provides inspection services. Dr. Fisher is thrilled to bring you his expertise and guidance to help you navigate regulatory compliance. His goal is for small, USDA-inspected meat processors to succeed and to understand how to best maintain compliance and reduce regulatory issues.

Last month we considered a slaughter hazard analysis. This month we will go a step further and consider a raw not ground and raw ground hazard analysis and flowchart.

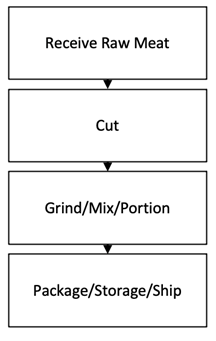

We start with the 9 CFR 417.2(a)(2) flow chart describing the process steps and product flow. Remember, a process is a series of steps conducted to an end, and a step is a unique activity that can encompass multiple actions. The end for a raw not ground/raw ground process is the conversion of wholesome carcasses and parts into raw single or multi-ingredient products. The process steps in the flowchart on the left achieve that end. The final step in the flowchart on the left encompasses multiple actions common to all processes. Establishments often include other steps such as Receive Packaging, Receive Ingredients, and Add Ingredients, but 9 CFR 417.2(a)(2) does not require that level of detail. The hazard analysis and flowchart are about the meat or poultry product, not the ingredients or packaging used to prepare the product.

We start with the 9 CFR 417.2(a)(2) flow chart describing the process steps and product flow. Remember, a process is a series of steps conducted to an end, and a step is a unique activity that can encompass multiple actions. The end for a raw not ground/raw ground process is the conversion of wholesome carcasses and parts into raw single or multi-ingredient products. The process steps in the flowchart on the left achieve that end. The final step in the flowchart on the left encompasses multiple actions common to all processes. Establishments often include other steps such as Receive Packaging, Receive Ingredients, and Add Ingredients, but 9 CFR 417.2(a)(2) does not require that level of detail. The hazard analysis and flowchart are about the meat or poultry product, not the ingredients or packaging used to prepare the product.

Next, we determine the food safety hazards reasonably likely to occur in the production process and identify the preventive measures the establishment can apply to control those food safety hazards reasonably likely to occur, starting with the first process step. The 9 CFR 417.2(a)(1) requirement is “determine food safety hazards reasonably likely to occur.” It is not “determine the food safety hazard NOT reasonably likely to occur,” or “determine non-food safety hazard reasonably likely to occur.”

Receive Raw Meat: One hundred percent of the raw meat received must comply with 9 CFR 318.1(a) or 9 CFR 381.145(a): “prepared only in an official establishment and previously inspected and passed by a Program employee.” If the product originated from the establishment slaughter process, that process controlled any food safety hazard reasonably likely to occur. If the product originated from another official establishment, “The mark of inspection means that FSIS has verified that the establishment has followed the HACCP process it has determined is necessary to produce safe product.”1 USDA’s FSIS Office of Investigation Enforcement and Audit Compliance and Investigations Division conducts surveillance of any person, firm, or corporation engaged in the business of storing or transporting raw meat in commerce to assure that they do not adulterate the raw meat. Therefore, absent organoleptic evidence of adulteration, a prudent establishment has no good reason to believe that a biological, chemical, or physical food safety hazard enters the process with the raw meat received at this step.

What about food safety hazard originating from insanitary facilities, equipment, utensils, and employees? A prudent establishment maintains 9 CFR 416 compliance, which prevents insanitary conditions and ensures that product is not adulterated during the Receive Raw Meat process step. A prudent establishment would not implement 9 CFR 417.1 preventive measures to control sanitary conditions controlled by other regulatory performance standards. So, our hazard analysis makes no determination that a biological, chemical, or physical food safety hazard is reasonably likely to occur during the Receive Raw Meat process step.

Cut: No food safety hazard carries over on the product from the previous process step into the Cut processes step. A prudent establishment maintains 9 CFR 416 compliance, which prevents insanitary conditions and ensures that product is not adulterated. A prudent establishment would not implement 9 CFR 417.1 preventive measures to control sanitary conditions controlled by other regulatory performance standards. So, our hazard analysis makes no determination that a biological, chemical, or physical food safety hazard is reasonably likely to occur during the Cut process step.

Grind/Mix/Portion: No food safety hazard carries over on the product from the previous process step into the Grind/Mix/Portion processes step. A prudent establishment maintains 9 CFR 318.6 and 9 CFR 416 compliance, which prevents insanitary conditions and ensures that product is not adulterated. A prudent establishment would not implement 9 CFR 417.1 preventive measures to control sanitary conditions controlled by other regulatory performance standards. So, our hazard analysis makes no determination that a biological, chemical, or physical food safety hazard is reasonably likely to occur during the Grind/Mix/Portion process step.

Package/Storage/Ship: No food safety hazard carries over on the product from the previous process step into the Package/Storage/Ship processes step. A prudent establishment maintains 9 CFR 317.24 or 9 CFR 381.144, 9 CFR 325.1(c) or 9 CFR 381.190(c), and 9 CFR 416 compliance, which prevents insanitary conditions and ensures that product is not adulterated. A prudent establishment would not implement 9 CFR 417.1 preventive measures to control sanitary conditions controlled by other regulatory performance standard. So, our hazard analysis makes no determination that a biological, chemical, or physical food safety hazard is reasonably likely to occur during the Package/Storage/Ship process step.

Hazard Analysis Complete! Surprised? To be expected. In 1997, FSIS published generic hazard analyses for each 9 CFR 417.2(b)(1) processing category and each generic hazard analysis identified at least one critical control point. The result was the false understanding that each 9 CFR 417.2(b)(1) processing category required a standalone 9 CFR 417.2(a) hazard analysis and that each hazard analysis must identify at least one food safety hazard reasonably likely to occur and one critical control point for that food safety hazard reasonably likely to occur. This false understanding persists today. Past articles and the above hazard analysis refute that false understanding.

There is no right or wrong way to conduct a hazard analysis. Choose one that works for you. Your hazard analysis should contain as much information as you need it to contain; not as much information as the FSIS inspector wants it to contain. More is not always better, or necessary. Keep it simple.

1. Paul Kiecker, Acting FSIS Administrator (personal communication, April 12, 2018).

More

As always, if you have a question, please use the Contact Us link and ask.

Did you miss Dr. Fisher’s previous posts?

YOUR FUND AT WORK

Services provided by FTCLDF go beyond legal representation for members in court cases.

Educational and policy work also provide an avenue for FTCLDF to build grassroots activism to create the most favorable regulatory climate possible. In addition to advising on bill language, FTCLDF supports favorable legislation via action alerts and social media outreach.

You can protect access to real foods from small farms by becoming a member or donating today.