We are pleased that Dr. Michael Fisher has joined the FTCLDF website as a regular contributor. Dr. Fisher is a retired United States Department of Agriculture (USDA) Food Safety and Inspection Services (FSIS) veterinarian, bringing decades of experience enforcing FSIS regulations during the slaughter and processing of animals for which the USDA provides inspection services. Dr. Fisher is thrilled to bring you his expertise and guidance to help you navigate regulatory compliance. His goal is for small, USDA-inspected meat processors to succeed and to understand how to best maintain compliance and reduce regulatory issues.

We are pleased that Dr. Michael Fisher has joined the FTCLDF website as a regular contributor. Dr. Fisher is a retired United States Department of Agriculture (USDA) Food Safety and Inspection Services (FSIS) veterinarian, bringing decades of experience enforcing FSIS regulations during the slaughter and processing of animals for which the USDA provides inspection services. Dr. Fisher is thrilled to bring you his expertise and guidance to help you navigate regulatory compliance. His goal is for small, USDA-inspected meat processors to succeed and to understand how to best maintain compliance and reduce regulatory issues.

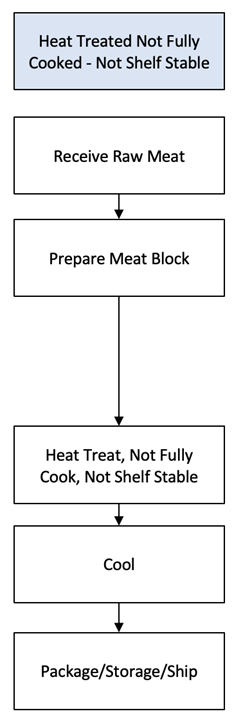

This month we consider a hazard analysis for the Heat Treated but Not Fully Cooked – Not Shelf Stable (HTNFCNSS) processing category. What is a HTNFCNSS product? If you do not know, you cannot conduct a hazard analysis.

- The Code of Federal Regulations (CFR) defines “product” to include any livestock or poultry carcass, part thereof, meat by-product, meat food product, or poultry food product capable of use as human food.[1]

- It is FSIS inspection policy that HTNFCNSS products are not ready-to-eat products produced using a heat process that is not adequate to achieve food safety, or is adequate to achieve food safety, but the final product is in a form that is not edible without additional preparation to achieve food safety.[2]

- It is FSIS inspection policy that a product is not shelf stable if it is perishable and cannot be safely stored at room temperature.[3]

What separates a HTNFCNSS product from Product with Secondary Inhibitors – Not Shelf Stable is the application of heat. What separates a HTNFCNSS product from Fully Cooked – Not Shelf Stable product is the standard of identity or a common or usual name that identifies the product as ready-to-eat.

What separates a HTNFCNSS product from Product with Secondary Inhibitors – Not Shelf Stable is the application of heat. What separates a HTNFCNSS product from Fully Cooked – Not Shelf Stable product is the standard of identity or a common or usual name that identifies the product as ready-to-eat.

Now that we have identified a HTNFCNSS product, we need a 9 CFR 417.2(a)(2) flow chart describing the process steps and product flow for preparing the HTNFCNSS product. The diagram to the left is such a flow chart. Remember, a process is a series of steps conducted to an end, and a step is a unique activity that can encompass multiple actions. Our end is a HTNFCNSS product.

Grounds, facilities, equipment, utensils, chemicals, non-meat ingredients, and employees are potential sources of food safety hazards and common to all process steps. Maintaining 9 CFR 416 compliance prevents insanitary conditions and ensures that product is not adulterated by grounds, facilities, equipment, utensils, chemicals, non-meat ingredients, and employees. Therefore, a 9 CFR 417.1 preventive measure is not required to control a potential food safety hazard originating from grounds, facilities, equipment, utensils, chemicals, non-meat ingredients, and employees because it is already controlled by another regulatory performance standard. So, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur due to grounds, facilities, equipment, utensils, and employees during the HTNFCNSS process.

Receive Raw Meat: Raw product is a potential source of food safety hazard. A federally inspected, HTNFCNSS product must be prepared from federally inspected product. 9 CFR 318.1(a) and 9 CFR 381.145(a) require that such products be “prepared only in an official establishment and previously inspected and passed by a Program employee” to ensure they are not adulterated. The mark of inspection means that FSIS verified that the producing establishment followed the Hazard Analysis Critical Control Point (HACCP) process it determined is necessary to produce safe product.[4] USDA’s FSIS Office of Investigation Enforcement and Audit (OIEA) Compliance and Investigations Division conducts surveillance of product in commerce to assure that such product is not adulterated. An establishment that maintains 9 CFR 318.1(a), 9 CFR 381.145(a) and 9 CFR 416 compliance is sufficiently assured that product received is not adulterated. Therefore, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur during this process step.

Prepare Meat Block: Preparing the meat block can involve cutting, grinding, adding ingredients, mixing, injecting, or stuffing. I choose to capture these activities within a single process step. An official establishment may choose differently. HTNFCNSS products may contain ingredients, which are potential sources of food safety hazards. 9 CFR 318.6(a) requires that ingredients not result in the product being adulterated. Non-meat and non-poultry ingredients are regulated by the Food and Drug Administration. FSIS accepts a guaranty by the ingredient supplier that the ingredient is safe for the intended use within the meaning of the Federal Food, Drug, and Cosmetic Act. A prudent establishment maintains such guaranty. No food safety hazard reasonably likely to occur carries over from the previous process step. Therefore, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur during this process step.

Heat Treat, Not Fully Cook, Not Shelf Stable: There is one method to transform the meat block into a HTNFCNSS product: apply heat. The application of heat can be smoking or fermenting to enhance flavor, par frying to set a batter, heating to achieve lethality, or some other application of heat. It is beyond the scope of this article to address all the possible applications of heat to HTNFCNSS product, so we will only address the most problematic. It is FSIS inspection policy that HTNFCNSS products include products that receive a full lethality treatment but there is no standard of identity defining them as fully cooked or a common or usual name that consumers understand as referring to ready-to-eat product.[5] This policy produces a clash between traditional technology, what regulations allow, and modern technology, what FSIS wants.

Traditional smoking and fermentation technology preserve product or impart flavor characteristics; but do not to fully cook product. Modern technology can accomplish the traditional objective and fully cook the product. Most traditional smoked or fermented products have no standard of identity, or common or usual name, that consumers understand as defining the product as fully cooked or ready to eat; therefore, they are HTNFCNSS products. Fully cooking does not change such product’s HTNFCNSS status. However, because a product is fully cooked, the producer can, but is not required to, treat the product as ready to eat. There is a difference between what FSIS wants and the regulations require. FSIS wants producers to treat fully cooked HTNFCNSS product as ready-to-eat product because such a product is subject to 9 CFR 430 requirements, which provide a higher standard of safety. The regulations allow producers to treat as not ready-to-eat, any fully cooked HTNFCNSS product with no standard of identity, or common or usual name, that consumers understand as defining the product as fully cooked or ready to eat.

Depending on the amount of heat applied and the length of application, microbial growth during this process step is a valid concern. 9 CFR 318.6(a) requires official establishments to furnish accurate information on all procedures involved in product preparation. The official establishment needs to implement a good manufacturing practice that controls microbial growth during the application of heat. An establishment that maintains 9 CFR 318.6(a) and 9 CFR 416 compliance is sufficiently assured that microbial growth was controlled and the product was not adulterated by the application of heat. No food safety hazard reasonably likely to occur carries over from the previous process step. Therefore, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur during this process step.

Cool: Microbial growth is a valid concern during cooling. The official establishment needs to implement a good manufacturing practice that controls microbial growth during the cooling. An establishment that maintains 9 CFR 318.6(a) and 9 CFR 416 compliance is sufficiently assured that microbial growth was controlled and the product was not adulterated by cooling. No food safety hazard reasonably likely to occur carries over from the previous process step. Therefore, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur during this process step. The Cool process step is a control point; however, because no food safety hazard is reasonably likely to occur, the Cool process step is not a critical control point.

Package/Storage/Ship: It is critical at this point in the hazard analysis to understand that the HTNFCNSS product is a not ready-to-eat product. Microbial growth has been controlled. The product is no more safe or unsafe than any other not ready-to-eat product. 9 CFR 317.2(k) and 9 CFR 381.125(a) require HTNFCNSS products to be labeled with Special Handling Statements (i.e., Keep Refrigerated, Keep Frozen, etc.). 9 CFR 317.2(k) and 9 CFR 381.125(a) require HTNFCNSS products destined for household consumers, hotels, restaurants, or similar institutions, that have not undergone other processing that would render them ready-to-eat, to be labeled with Safe Handling Instruction. An establishment that maintains 9 CFR 317.2(k) and 9 CFR 381.125(a) compliance is assured that the consumer is sufficiently informed on the proper handling of the product to ensure food safety.

Packaging, storage, and shipping are activities common to all processing categories, regardless of the product prepared. I choose to capture them within a single process step. An official establishment may choose differently. 9 CFR 317.24 or 9 CFR 381.144 and 9 CFR 325.1(c) or 9 CFR 381,190(c) require that packaging materials and transport methods, respectfully, not result in product being adulterated. An establishment that maintains 9 CFR 317.24 or 9 CFR 381.144 and 9 CFR 325.1(c) or 9 CFR 381,190(c) and 9 CFR 416 compliance is sufficiently assured that the product was not adulterated during packaging, storage, and shipment. No food safety hazard reasonably likely to occur carries over from the previous process step. Therefore, our hazard analysis makes no determination that a food safety hazard is reasonably likely to occur during this process step.

Hazard Analysis Complete! Key to conducting a HTNFCNSS hazard analysis is the realization that any hazard analysis rests on a foundation of sanitation and that there is a difference between what FSIS wants and what the regulations require. Absent that foundation of sanitation, conducing a HTNFCNSS hazard analysis is a waste of time because without sanitation, product that is not adulterated cannot be produced. Absent knowing the difference between what FSIS wants and what the regulations require, conducing a HTNFCNSS hazard analysis can be problematic because you are going against what the regulations require. Never a good idea.

Footnotes

[1] 9 CFR 301.2 and 9 CFR 381.1

[2] USDA, FSIS. (2019) FSIS Product Categorization (Guideline ID: FSIS-GD-2019-0010). https://www.fsis.usda.gov/guidelines/2019-0010

[3] USDA, FSIS. (2019) What does “shelf stable” mean? (Knowledge Article). https://ask.usda.gov

[4] Paul Kiecker, Acting FSIS Administrator (personal communication, April 12, 2018)

[5] USDA, FSIS. (2019) FSIS Product Categorization (Guideline ID: FSIS-GD-2019-0010). https://www.fsis.usda.gov/guidelines/2019-0010

More

As always, if you have a question, please use the Contact Us link and ask.

Did you miss Dr. Fisher’s previous posts?

YOUR FUND AT WORK

Services provided by FTCLDF go beyond legal representation for members in court cases.

Educational and policy work also provide an avenue for FTCLDF to build grassroots activism to create the most favorable regulatory climate possible. In addition to advising on bill language, FTCLDF supports favorable legislation via action alerts and social media outreach.

You can protect access to real foods from small farms by becoming a member or donating today.